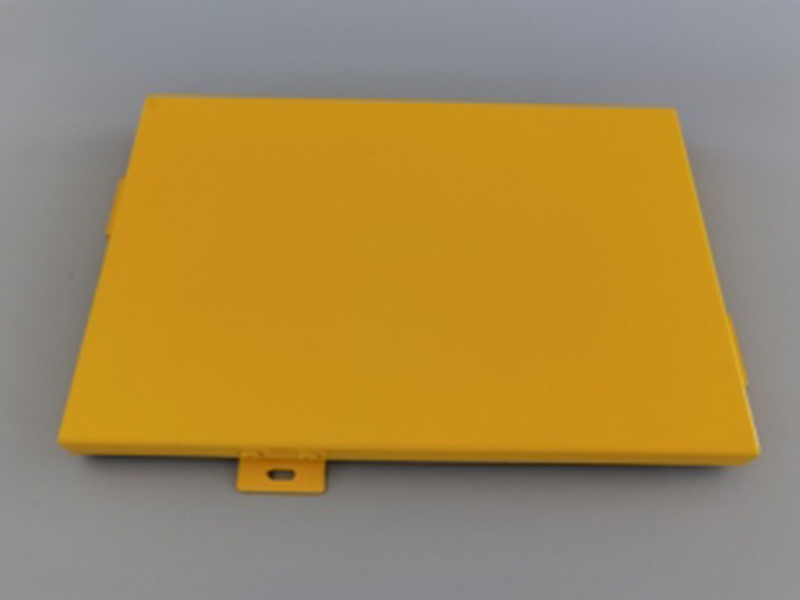

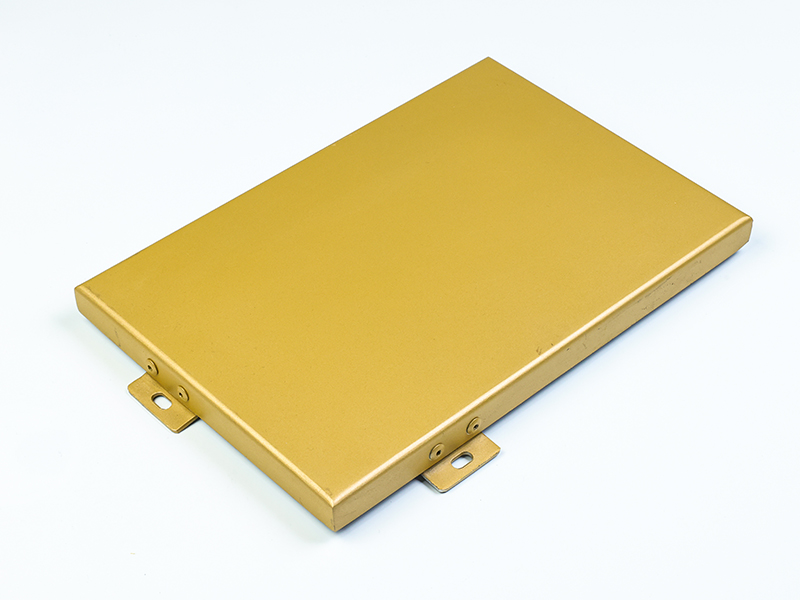

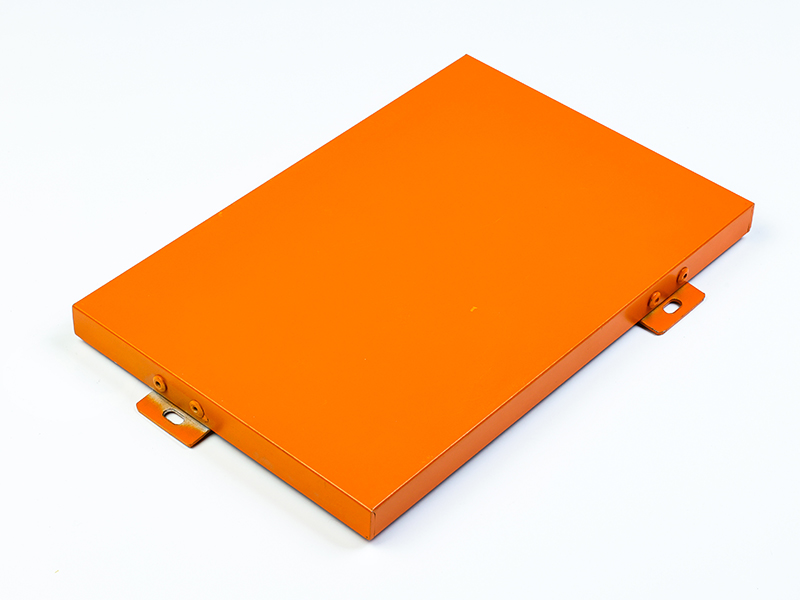

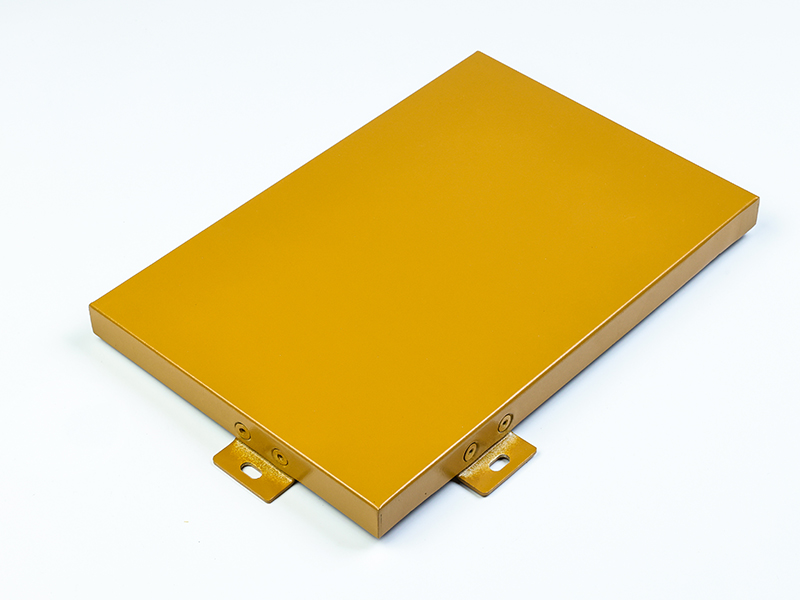

Powder Coated Aluminum Panels / Fluorocarbon Aluminum Panel Manufacturers

-

The company has a large production base, a variety of aluminum product processing equipment, CNC equipment, professional processing centers and other reliable production lines. The company has established production, supply, sales and logistics support systems, with a complete organizational structure. The company has strong R&D, design, production and sales capabilities, as well as good management level, and can provide customers with customized and professional services.

Classification

Fluorocarbon aluminum panel

- Phone:+86-13921258783

- E-mail:huhuizhong@mingalu.com

Detail

In our communication with clients, we have found that many of them are confused about fluorocarbon sprayed aluminum veneer and powder sprayed aluminum veneer. What are the differences between these different spraying processes for aluminum veneer?

Powder coating aluminum veneer processing and fluorocarbon coating processing do look very similar on the surface, and it is generally not noticeable to non professionals unless they have many years of experience in this industry. There are many differences. To summarize, let's analyze them in detail from the following points

- In terms of performance:

Fluorocarbon spray is commonly used outdoors, while powder spray aluminum veneer is commonly used indoors. - In terms of price:

Fluorocarbon spraying is slightly more expensive than powder spraying aluminum veneer, but the price of bright powder spraying aluminum veneer is also high, not a one size fits all approach! - Actual usage:

Curtain wall aluminum veneer, especially in the past 5 years of use, according to the curtain wall design and construction units, as well as the sales situation of aluminum veneer factories, fluorocarbon spraying is generally used for the surface of curtain wall aluminum veneer and outdoor profiles, while powder coating aluminum veneer is more commonly used for indoor profiles, and anodizing treatment is also used for concealed parts.

In the past few years, it was mainly powder coated aluminum veneer, but in recent years, with the widespread use of heat-insulating profiles and the rise of the market, fluorocarbon coated aluminum veneer has also been widely used. Except for a few villas and government projects that use fluorocarbon spraying, all others use powder coated aluminum veneer. - Outdoor aluminum profiles, including curtain wall pressure plates, buckle plates, decorative panels, exterior wall aluminum veneers, exterior wall aluminum grilles, balcony perforated aluminum panels, etc., should be treated with fluorocarbon spraying, otherwise they are prone to fading and surface cracks, especially in areas with frequent wind and rain, sun and rain exposure, high wind pressure, and strong ultraviolet radiation, which require high-quality surface treatment; For non outdoor curtain wall profiles, such as curtain wall columns, beams, etc., it is recommended to use powder coated aluminum veneer. For window profiles, considering factors such as building effect, property positioning, cost, construction, functional use, and durability, it is recommended to use fluorocarbon coating for the outdoor part of the thermal insulation profile and powder coated aluminum veneer for the indoor part.

1、 Fluorocarbon aluminum veneer

We can customize various complex geometric shapes of any size, shape, and difficulty according to customer needs. We can bend, punch, and roll arcs to present various shapes.

*Having a professional production base and various types of aluminum product machining equipment

*A company that integrates research and development, production, sales, installation, and technical services

2、 Product advantages

(1) National standard aluminum plate: Carefully selected pure aluminum material with a thickness of 3.0mm, sturdy and heavy, using A00 aluminum ingots.

(2) Reinforcement design: The width and density design of all reinforcement bars in the bright aluminum veneer.

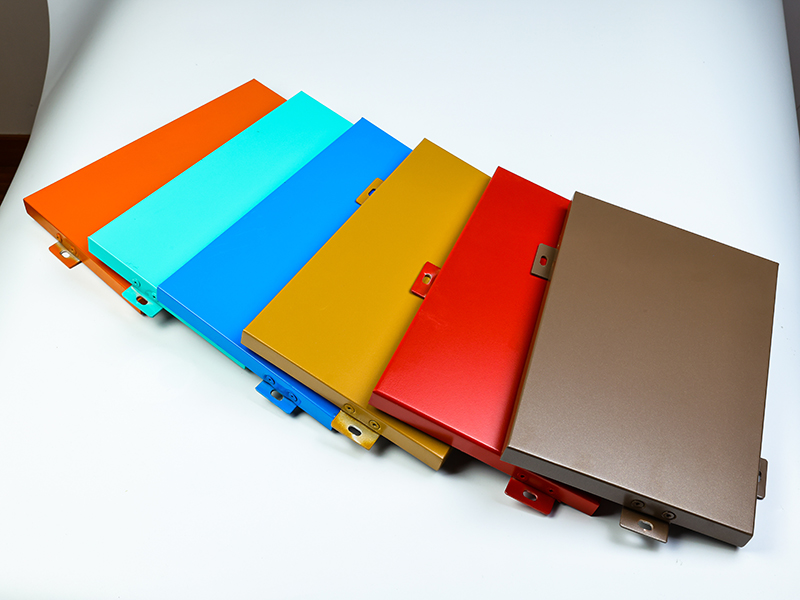

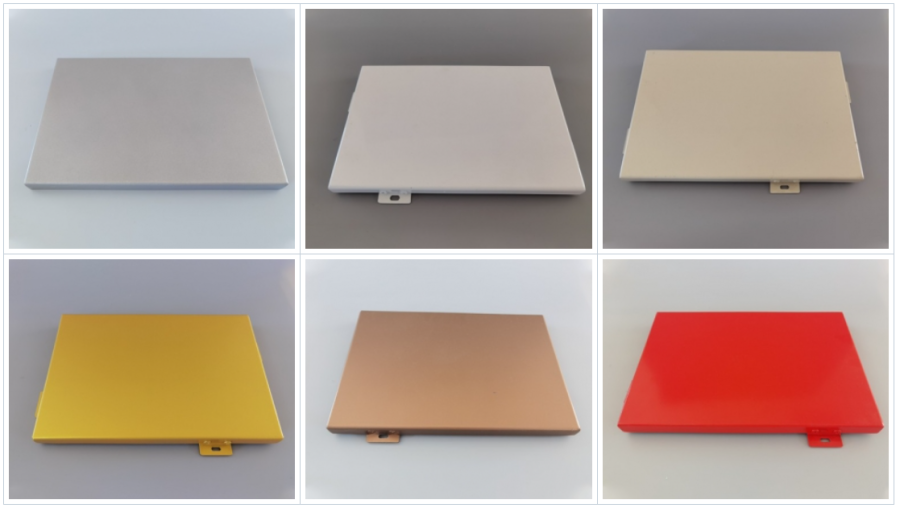

(3) Rich colors: Bright aluminum veneer has a wide range of colors and can imitate various textures such as stone and wood, with realistic effects. It uses electrostatic spraying technology to ensure even and exquisite adhesion between paint and aluminum plate, creating a beautiful and atmospheric appearance.

(4) On demand customization: Various complex geometric shapes of any size, shape, and difficulty can be customized according to customer needs, including bending, punching, and arc rolling, presenting various shapes.

(5) Product testing: From raw material procurement to semi-finished product production, and then to product packaging and delivery, we strictly control every link and process to ensure every product.

(6) Application areas: Widely used in various building interior and exterior walls, lobby facades, column decorations, elevated corridors, beams and columns, airports, stations, hospitals, pedestrian overpasses, indoor irregular ceilings, etc.